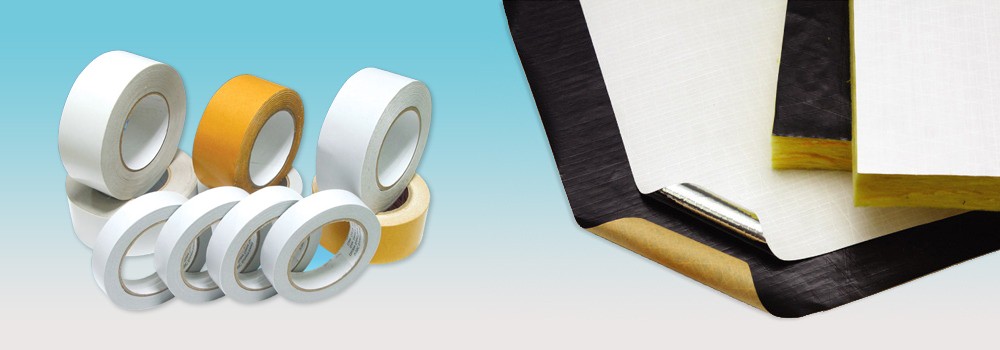

The specification of the tape consists of three layers,

Backing:Special blend of stabilized polyolefines

Adhesive:Butyl rubber Bituminous Compound and Adhesion Promoting Resins

Interleaf:Antiadhesive Film Treated with Silicone

|

53Polyolefin anticorrosive tape

Item No.: Conet-54 |

Polyolefin anticorrosive tape: Cold applied tape coating system designed for the corrosion protection of field joints, fittings, and specialty piping&waterproofing. The highly conformable backing and thick, aggressive adhesive also make it the ideal repair system for all types of main line coatings.

The tape with very tacky adhesive has a release plastic liner to enable proper unwinding of the roll. Whether used as a single wrap with a mechanical layer or a double wrap system, the 934 tape coating system is universally specified in the oil, gas and water industries

It could be applied after the primer by hand or with a wrapping machine.

Features

Excellent adhesion to pipe and self

Flexibility provides extra protection at vulnerable areas

Excellent conformability and consistent uniform thickness

Easily applied with no special equipment

Compatible with common pipe coatings

Excellent resistance to cathodic disbonding

Resistant to UV

Can be applied over a wide temperature range

Good conformability and consistent uniform thickness

Cold applied

Heavy duty butyl bitum

Technical datas:

|

UNIT |

TEST METHOD |

TYPICAL VALUES |

||||

|

|

934-40 |

934-50 |

934-60 |

934-65 |

||

|

Total thickness |

mil |

ASTM D 1000 |

40mils |

50mils |

60mils |

65mils |

|

Tensile Strength |

lb/in |

ASTM D 1000 |

30(5kg/cm) |

35(6.3kg/cm) |

39(7kg/cm) |

42(7.5kg/cm) |

|

Elongation |

% |

ASTM D 1000 |

400 |

400 |

450 |

500 |

|

Length |

|

|

25mtrs |

20mtrs |

15mtrs |

10mtrs |

|

Width |

|

|

2”,4”,6”,9” |

|||

|

Peel adhesion To primed pipe |

oz/in |

ASTM D 1000 |

269(3kg/cm) |

296(3.3kg/cm) |

314 (3.5kg/cm) |

340(3.8kg/cm) |

|

To backing |

oz/in |

ASTM D 1000 |

90(1kg/cm) |

90(1kg/cm) |

117(1.3kg/cm) |

135(1.5kg/cm) |

|

Dielectric Strength |

KV/mm |

ASTM D 1000 |

42 |

42.6 |

43 |

43.8 |

|

Volume Resistivity |

ohm·m |

ASTM D 257 |

2.5 X 1012 |

2.5 X 1012 |

2.5 X 1012 |

2.5 X 1012 |

|

Water Vapor Transmission Rate |

g/ m2 /24h |

ASTM E 96 |

0.06 |

0.05 |

0.03 |

0.02 |

|

Water Absorptivity |

% |

ASTM D 570 |

0.1 |

0.1 |

0.1 |

0.1 |

|

Application Temperature |

°F |

|

-31-+160 (-35-+70℃) |

|||

|

°F |

|

-40-+176 (-40-+80℃) |

||||