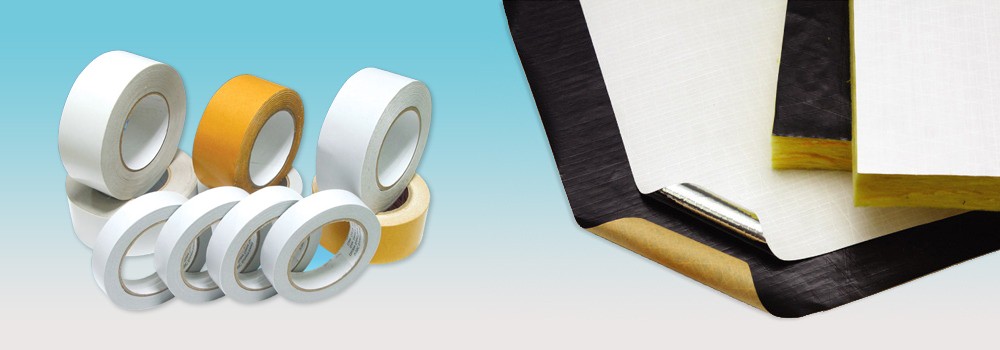

1.Product Overview

The product is made of PVDF film + butyl polymer self-adhesive layer + isolation film composite. The PVDF membrane itself has hydrophobicity and airtightness, which can eliminate the penetration of water molecules.

PVDF film itself has hydrophobicity and airtightness, which can eliminate the penetration of water molecules, and also has strong anti-UV, outdoor weathering, anti-corrosion performance, which is a rare exposed material.

The adhesive layer is mainly dominated by imported polymer polymers, with other additives and fillers.

The adhesive layer is mainly made of imported high polymer multi-phase polymer with other additives and fillers, and processed according to a special production formula.

2.Product Use

Suitable for all kinds of roof waterproof repair, but also play a role in cooling, heat insulation, anti-corrosion, noise reduction.

3.Product Features

(1) Does not contain any solvent, safe and environmentally friendly;

(2), with excellent exposed performance, service life of about 20 years;

(3), product performance in line with GB/T23260-2009 "waterproofing membrane with self-adhesive layer;

(4), has excellent chemical resistance, weather resistance and corrosion resistance;

(5), without open flame construction, easy to use;

(6), the original roof does not need to be dismantled, does not affect the production, storage, has a certain cost advantage.

4.Technical parameters

(1) Density: 1.1~1.6 g/cm3;

(2) Holding viscosity (min): ≥ 20

(3) Heat resistance: 120℃, 2h No flow, cracking, deformation;

(4), low-temperature bending: -40 ℃ without cracks;

(5), peeling strength: ≥ 10 N / cm.

(6), aging resistance (xenon lamp): 12000h ΔE ≤ 4;

5. Method of use

(1) Clean up the grass-roots level - grass-roots pretreatment;

(2) coil positioning - pre-laying coil;

(3) Paving coil - joint bonding, compaction;

(4) quality acceptance.

6ã€Packaging and storage

(1) Packed in rolls (specifications can be specified);

(2) Storage conditions: cool, dry, well ventilated and out of direct sunlight; (3) Shelf life: 24 months under specified storage conditions and temperatures.

(3) Shelf life: 24 months under the specified storage conditions and temperature.

Remarks:

Product thickness: 0.4~1.5mm

Product width: ≤1200mm

Common colours of PVDF film: white grey, navy blue, iron grey, scarlet.